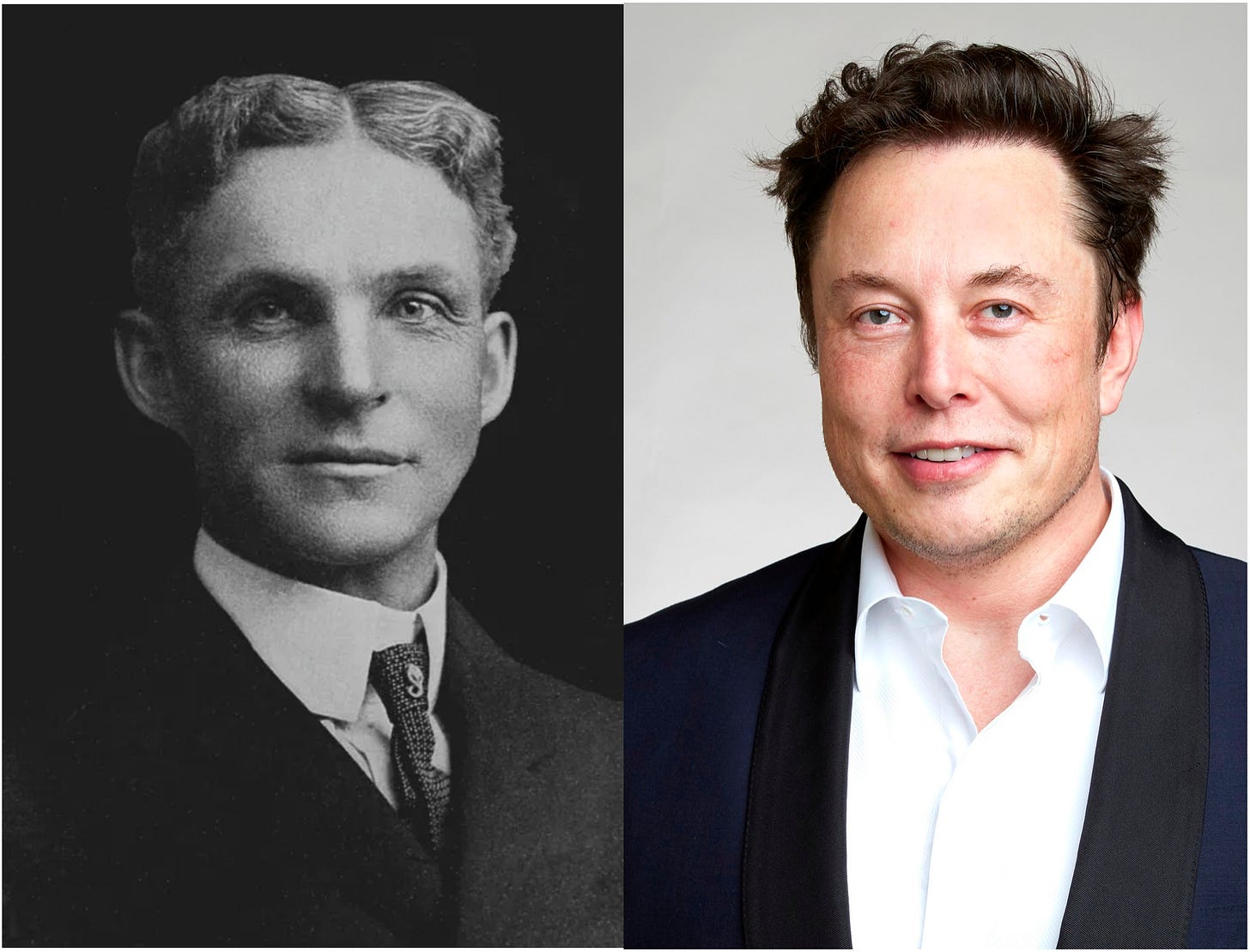

Elon Musk is often compared to Henry Ford—and for good reason. Ford reduced the time to assemble a Model T chassis from 12 hours and 8 minutes in 1910 to just 93 minutes in 1914—a remarkable 87.2 percent reduction. In the time it once took to build a single Model T, Ford could now produce nearly eight.

Tesla’s Model Y, the world’s best-selling car for multiple years, rolls off the line every 35 seconds at the company’s Shanghai factory, the most productive car plant in the world. In 2020 Tesla replaced 70 underbody parts with a single permanent casting.

Musk recently announced that the company’s upcoming Cybercab robotaxi will roll off the production line every 5 seconds. This is seven times faster than the Model Y plant. Riz Akhtar notes that:

These savings will come from parts reduction, manufacturing methods, automated production lines and materials technologies, which will help it get to that price point that’s cheaper than any Tesla model the company sells today.

On parts reduction, an engineer on the Cybercab program revealed that the total structural parts count in the Cybercab would stand at roughly 80 when compared to the Model Y, which has around 200 parts.

Seven times faster with 60 percent fewer parts. Henry would be very proud of Elon.

Learn more about our infinitely bountiful planet at superabundance.com. We explain and give hundreds of examples why more people with freedom means much more resource abundances for everyone in our book, Superabundance, available at Amazon.

Gale Pooley is a Senior Fellow at the Discovery Institute, an Adjunct Scholar at the Cato Institute, and a board member at Human Progress.